Automatic Sprinkler Systems

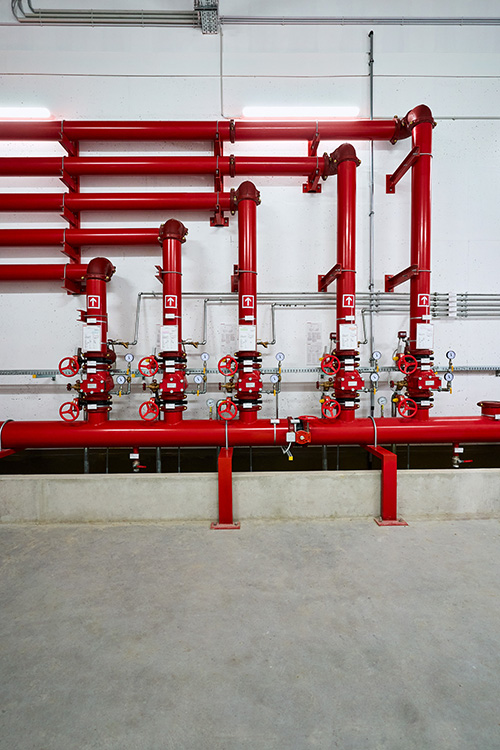

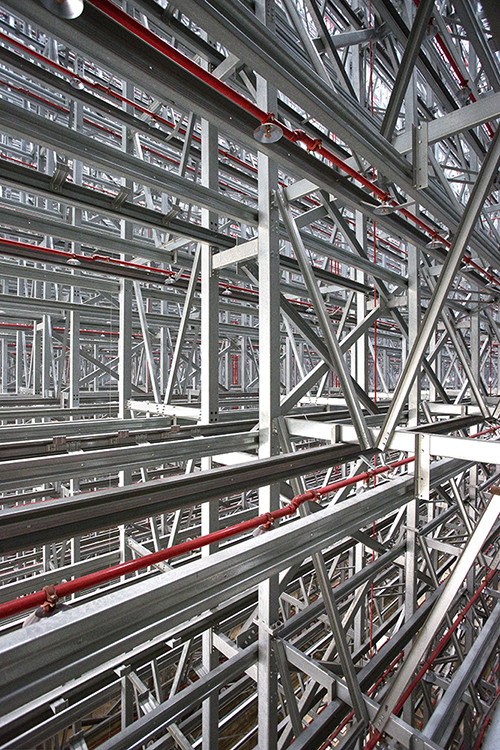

Sprinkler systems are vital components in fire protection strategies, offering automated and reliable firefighting capabilities across diverse environments. These systems consist of a water supply, pump, alarm valve stations, and interconnected pipes with strategically positioned sprinkler heads, providing rapid response to fire outbreaks.

FUNCTIONALITY

The functionality of a sprinkler system lies in its ability to automatically detect and suppress fires. These systems remain inactive until triggered by specific conditions indicative of a fire. Heat detection is the most common activation method, where an increase in temperature breaks the thermal fuse of the sprinkler head and thus activates it, causing a drop in pressure within the pipeline, subsequently initiating the opening of the alarm valve and activating the sprinkler system. Upon reaching a predetermined temperature, individual sprinkler heads open, releasing water in a controlled shower stream onto the fire-affected area.

Operation

A fundamental aspect of sprinkler systems is their targeted approach to fire suppression. Only the sprinklers closest to the fire or within its vicinity are activated. This precision minimizes water damage to unaffected spaces while effectively containing and extinguishing the fire.

Versatility and adaptability

Sprinkler systems are adaptable to various environments, catering to specific fire risk factors and operational requirements. Their versatility, offered through wet, dry, and pre-action systems, ensures tailored and effective fire suppression solutions for industrial, commercial, and residential settings.

Conclusion

Incorporating sophisticated detection and activation mechanisms, sprinkler systems stand as proactive safeguards, swiftly addressing fire outbreaks while mitigating potential damage and ensuring the safety of occupants within the protected space.

Types of Sprinkler Systems

- Wet Pipe Systems: In these systems pipes are filled with water at all times, ready for immediate discharge upon activation. They are commonly used in environments where freezing temperatures are not a concern.

- Dry Pipe Systems:Instead of water, the pipes leading up to the dry pipe valve are filled with pressurized air or nitrogen. Upon activation, the air or nitrogen releases, the pressure in the system drops, allowing the dry pipe valve to open, enabling water to flow into the system and suppress the fire. Dry pipe systems are beneficial in areas where water might freeze and compromise the functionality of traditional wet pipe systems.

- Pre-action Systems:According to the EN 12 845 standard, we distinguish between type A and type B Pre-action Systems.

- Type A is an otherwise normal dry pipe system in which the alarm valve is activated by an automatic fire detection system, but not by the operation of the sprinklers. In the event of a fault in the fire detection system, the system should operate as an ordinary dry pipe system. Type A system is only recommended in areas where considerable damage could occur from accidental water discharge.

- Type B also resembles a typical dry pipe system but has dual activation—either through an automatic fire detection system or by sprinkler operation. Independently of the response of the detectors, a pressure drop in the pipework causes the alarm valve to open. Type B systems might be installed wherever a dry pipe system is called for and the fire spread is expected to be rapid.